The Future of Anodizing Software

We have no doubt that Control It will benefit your production line, but in case you don’t believe us, here are just some of the things that Control It can do for you:

Included Features:

- Comes coded with all anodizing types for both aluminum and titanium

- Operate multiple rectifiers from a single workstation

- Allow your rectifiers to function without an operator’s supervision

- Use window docking to see processes in progress with a glance

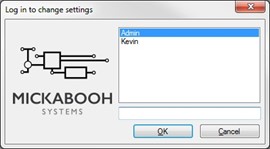

- Operator permissions lets only qualified staff access vital functions

- Complete process documentation including work orders & part numbers

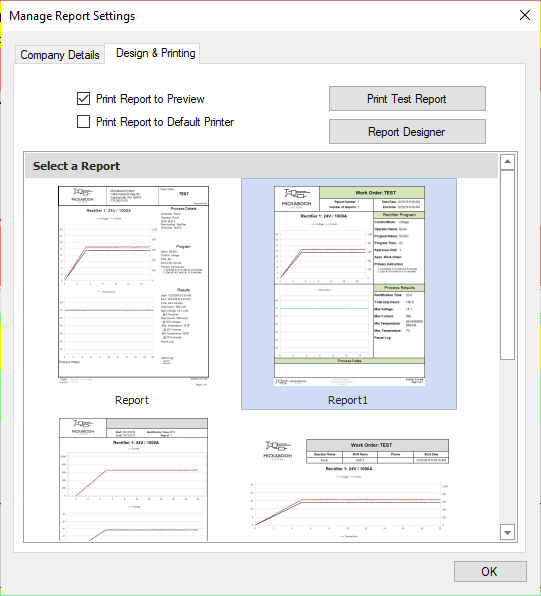

- Custom reports that include all the information that is important to you

- Creates a searchable database to easily locate previous reports

- Use the Process Queue to set up your line

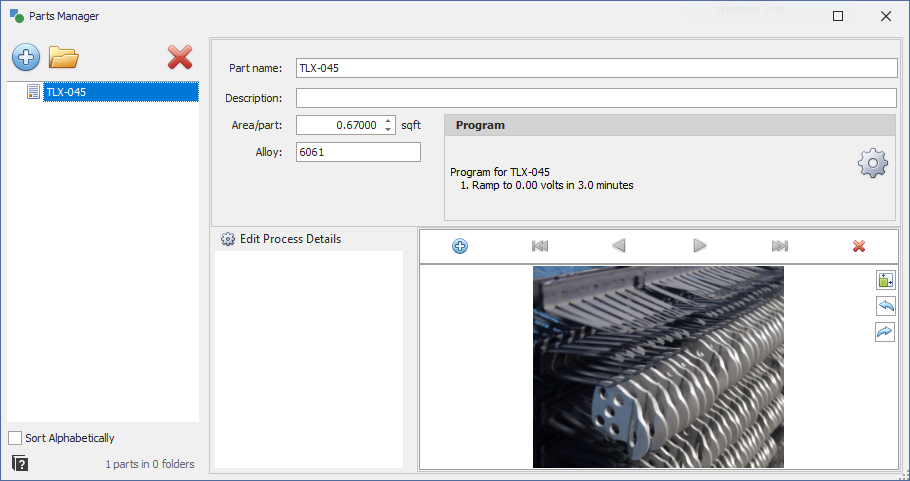

- Allows you to create custom programs, with as much instruction as you want

- Create and store pulsing profiles to save parts from burning

- Build virtual part-profiles to easily run repeat processes

- Use the “Quick Start” feature to run using 720 parameters

- Built in amp-hour limiter fits any existing rectifiers with minimal installation impact

- Completely scalable – Whether you have 1 rectifier or 100, Control It will grow right alongside your business

- The “Load Sizing” feature allows you to remove work orders during a process and generate its documentation immediately

- The “Add Plating” feature allows you to extend your process run time for as long as you need

- Use “Run by Parts” to keep track of part info while running their associated program