Load Splitting

Control It’s load splitting feature allows you to easily remove parts from running processes. This feature comes in handy when some of the parts in the bath build the anodic coating slightly faster (or slower) than others. If this happens, the operator can remove the parts that are done, and leave the rest to run longer. If the load split was done while running a current density program, the rectifier’s output current will be reduced according to the amount of area removed.

The operator can remove an entire work order or just part of it. If an entire work order is removed, the report for the work order will be printed. If only part of the work order is removed, the load split is logged and the report will be printed when the run is complete. Either way, all load size changes are fully documented on each report.

Note: Load splitting is not allowed for current controlled programs. Load splitting is only allowed for voltage and current density control programs.

The operator will have the opportunity to adjust the process area in the bath when a program resumes from a paused condition regardless of what initiated the pause condition (the operator clicking the pause button, a program pause, etc.)

After resuming, the operator will be asked if the load size has changed. If ‘No’ is clicked, the process will continue with no changes. Clicking Yes will open the Load Size Manager allowing the operator to remove all or some of the area in the process.

After resuming, the operator will be asked if the load size has changed. If ‘No’ is clicked, the process will continue with no changes. Clicking Yes will open the Load Size Manager allowing the operator to remove all or some of the area in the process.

The Load Size Manager will show all of the work orders in the process and how much area each work order has. To remove the entire work order, check the Remove All column for the work order. To remove only part of the work order, enter the amount of area to remove.

The Load Size Manager will show all of the work orders in the process and how much area each work order has. To remove the entire work order, check the Remove All column for the work order. To remove only part of the work order, enter the amount of area to remove.  After entering the amount of area to remove, and clicking the OK button, the operator will be prompted to confirm the change. Clicking ‘Yes’ will update the process and resume the run.

After entering the amount of area to remove, and clicking the OK button, the operator will be prompted to confirm the change. Clicking ‘Yes’ will update the process and resume the run.

Note: The operator cannot remove all of the work orders from the Load Size Manager. If all work orders are to be removed, the run should be stopped.

Should the load need to be split again, the Load Size Manager will open and show the area that is remaining in the bath. Work orders that have been removed will show a strike though the work order number.

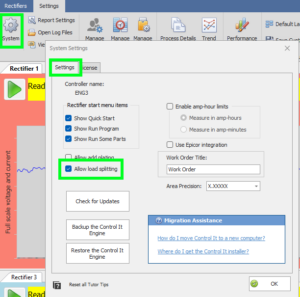

Using the Mickabooh Control & Tracking System, you can process multiple work orders each with a different coating thickness requirement in the same run. To allow your operators to use this feature, the Allow load size changes options must be set for each rectifier. Open the rectifier settings by clicking Rectifier > Settings menu item. When the Rectifier Settings window opens, make sure to select the Allow load size changes option. This is a rectifier specific option and must be set for each rectifier that load size changes will occur.

When load size changes are enabled, the operator will be able to adjust the load size when a program is resumed from a pause. Load size changing is allowed when one of the following are true,

- The process is running either a Current Density Control program or a Voltage Control program (see Creating Programs for information about Current Density programs) OR

- The program is associated with a part (see Working with Parts) for information about Parts)

As mentioned above, when the allow-load-size-changes setting for a rectifier is enabled, the operator will have the opportunity to adjust the process area in the bath when a program resumes from a paused condition. It doesn’t matter what initiated the pause condition (either by the operator clicking the pause button, program pause, etc).

As an example of how to change the load size, assume you are running a mixed load with 3 work orders; each with a varying amount of process area. Work order #1 has 10 square feet, work order #2 has 20 square feet and work order #3 has 30 square feet. The operator puts the entire load (total 60 sqft) into the process tank and runs a program to ramp to 18 ASF and hold there for 60 minutes. After running 30 minutes, the operator pauses the process and removes all of the parts that constitute work order #2 (20 square feet). When the operator clicks the Resume button he will be asked if the load size has changed. Clicking Yes will allow the operator to adjust the load size in the process bath. If the load size has not changed, the operator should click No. Clicking Cancel will cancel the Resume operation and the process will remain paused.

If the operator chooses to change the load size the Change Load Size window will appear with all of the work orders listed. The operator can then either select the work order(s) to remove, or he can select the amount of process area that has been removed. For our example, the operator removed the material for work order #2, so he would click work order #2. The operator cannot remove a work order AND specify the area. He must either select a work order OR enter the amount of area removed. If the operator clicks the cancel button, the load size will not be changed and the process will remain paused.

If the operator selects area to remove and clicks OK, a confirmation box will be shown and the user can either accept the change or not. If the operator clicks No, the load size will not be changed and the process will remain paused. If the operator clicks Yes, the process load size will be changed and the rectifier’s current output will be adjusted to maintain the correct current density. The rectifier will then begin its pre-process count down and the program will resume in the normal fashion.

There is no limit to the number of times you can adjust the load size during a process. You can run as many work orders with different coating requirement as you need.

Load size changes are also recorded on the process report and in the process data files. When the process report is created, it will state when a load size change occurred and how much area was removed. The report will also state when a particular work order was pulled from the process bath.